Smart Home Manufacturing Plant: Industrial IoT

Imagine a world where smart homes aren't just dreamt up in Silicon Valley, but efficiently and sustainably manufactured right here. We're talking about a new era of production, where interconnected devices and intelligent systems work in harmony to create the very foundations of the connected lifestyle.

It's no secret that building these intricate smart home devices and systems comes with its share of headaches. Juggling complex supply chains, ensuring consistent quality across thousands of components, and keeping costs competitive in a rapidly evolving market are just a few of the challenges manufacturers face.

The key is to embrace the Industrial Internet of Things (IIo T) – a network of sensors, software, and analytics that transforms manufacturing plants into intelligent, responsive ecosystems. It's about creating a seamless flow of information, from the factory floor to the boardroom, empowering manufacturers to make smarter decisions, optimize their processes, and ultimately, deliver better smart home products to consumers.

This article delves into the world of smart home manufacturing plants powered by IIo T. We'll explore how interconnected devices, data-driven insights, and advanced automation are revolutionizing the production of smart home technology. Keywords like predictive maintenance, real-time monitoring, supply chain optimization, and digital twins will become your new best friends as we unpack this exciting transformation.

The Heart of the Smart Factory: Connectivity

I remember touring a traditional manufacturing plant a few years ago. The noise was deafening, the processes seemed chaotic, and information flowed slowly, mostly on paper. It felt like stepping back in time. Now, imagine the opposite: a smart factory buzzing with data, where machines communicate seamlessly, and every component is tracked in real-time. That's the power of connectivity.

The core of a smart home manufacturing plant lies in its ability to connect every aspect of the production process. Sensors embedded in machines monitor performance, predict potential failures, and trigger preventative maintenance. This reduces downtime, extends equipment lifespan, and improves overall efficiency. Real-time data streams provide insights into everything from raw material inventory to finished product quality. This allows manufacturers to identify bottlenecks, optimize workflows, and ensure consistent quality across the entire production line. Furthermore, connected supply chains enable manufacturers to track components from origin to assembly, improving transparency and reducing the risk of counterfeit parts. Ultimately, this increased connectivity translates to lower costs, faster production times, and higher-quality smart home products for consumers.

What Exactly is IIo T in Smart Home Manufacturing?

At its core, IIo T in smart home manufacturing involves using connected devices, sensors, and software to collect and analyze data from every stage of the production process. Think of it as giving your factory a nervous system, capable of sensing, interpreting, and responding to its environment.

This data is then used to optimize various aspects of the manufacturing process, from predicting equipment failures to streamlining supply chains and improving product quality. IIo T enables manufacturers to move from reactive problem-solving to proactive optimization. Imagine being able to predict when a machine is likely to fail and schedule maintenance before it causes a disruption, or being able to track a component from the moment it leaves the supplier's warehouse to the moment it's installed in a smart thermostat. That's the power of IIo T. It's about creating a closed-loop system where data informs decisions, decisions drive improvements, and improvements lead to a more efficient and profitable operation.

The History and Myths of Smart Manufacturing

The idea of automated manufacturing isn't new. We can trace it back to the early days of the Industrial Revolution, with innovations like the assembly line. However, the IIo T takes things to a whole new level.

One common myth is that IIo T is only for large corporations with deep pockets. The truth is that even small and medium-sized enterprises (SMEs) can benefit from implementing IIo T solutions. There are affordable and scalable platforms available that allow manufacturers of all sizes to connect their equipment, collect data, and gain valuable insights. Another myth is that IIo T is too complex to implement. While it's true that setting up an IIo T system requires careful planning and expertise, there are many experienced integrators who can guide manufacturers through the process. The key is to start small, focus on specific use cases, and gradually expand the system as needed. Over time, many believe IIo T to be a magic pill for any manufacturing challenge, but reality tells us that the truth lies in the successful integration of hardware, software, human expertise, and continuous improvement.

Unveiling the Hidden Secrets of IIo T Success

While the potential benefits of IIo T are clear, achieving real success requires more than just installing sensors and collecting data. There's a hidden layer of strategy, planning, and cultural change that's often overlooked.

One of the biggest secrets is the importance of data quality. Collecting massive amounts of data is useless if the data is inaccurate, incomplete, or irrelevant. Manufacturers need to invest in data validation and cleansing processes to ensure that the information they're using to make decisions is reliable. Another secret is the need for a skilled workforce. IIo T requires people with expertise in data analytics, cybersecurity, and industrial automation. Manufacturers need to invest in training and development to ensure that their employees have the skills necessary to operate and maintain these systems. Finally, there's the secret of cultural change. IIo T requires a shift in mindset, from a reactive approach to a proactive one. Employees need to be empowered to use data to make decisions and to continuously improve processes. This requires a culture of collaboration, innovation, and continuous learning.

Recommendations for Smart Home Manufacturing with IIo T

So, you're ready to dive into the world of IIo T for your smart home manufacturing plant? Here's some advice to get you started on the right foot.

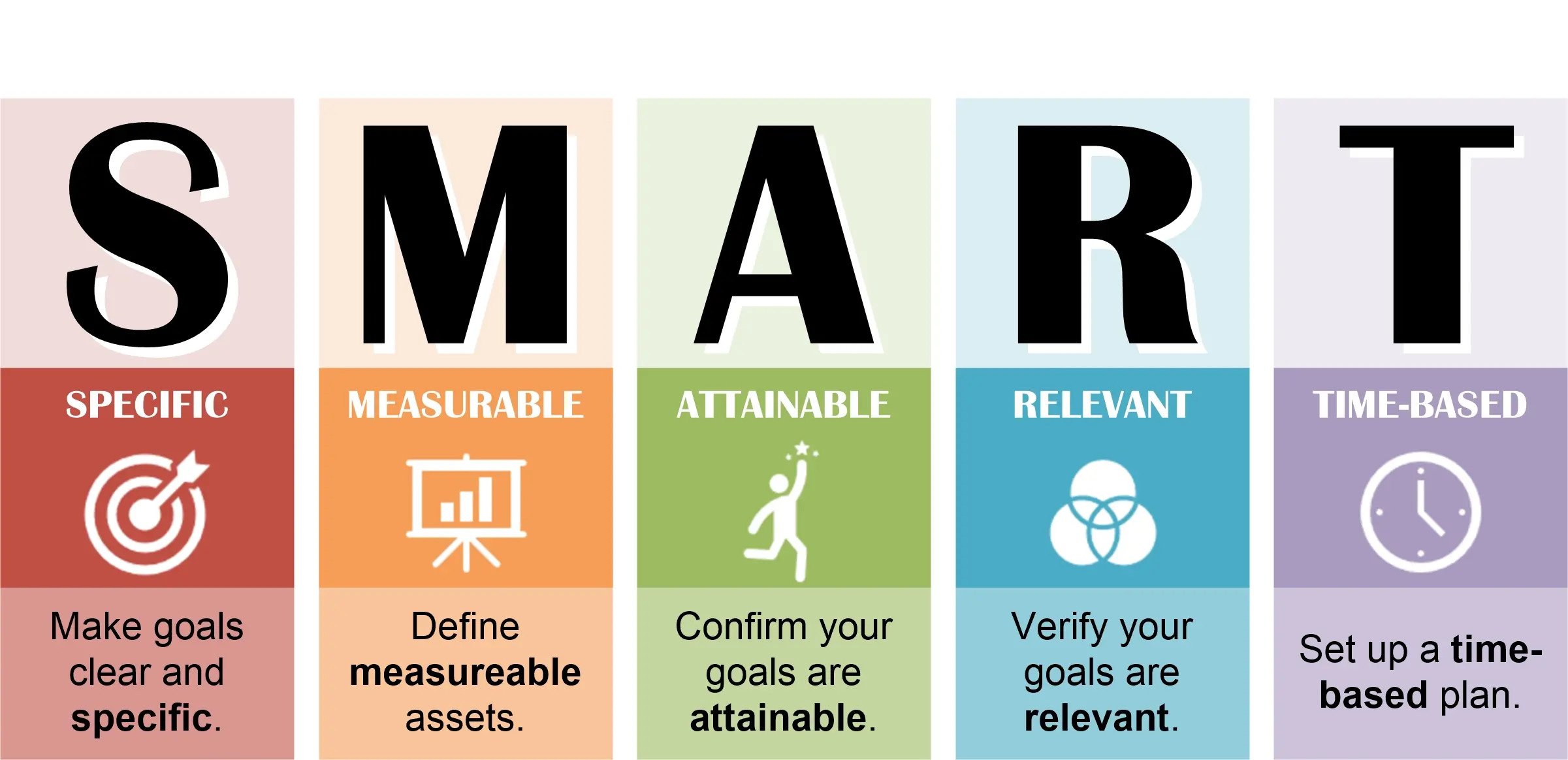

First, define your goals. What are you hoping to achieve with IIo T? Are you trying to reduce downtime, improve quality, or optimize your supply chain? Having clear goals will help you focus your efforts and measure your success. Second, start small. Don't try to implement everything at once. Choose a pilot project, such as monitoring the performance of a critical machine, and use that as a learning experience. Third, invest in the right technology. There are many different IIo T platforms and solutions available. Choose a platform that is scalable, secure, and easy to use. Fourth, partner with an experienced integrator. An integrator can help you design, implement, and maintain your IIo T system. Finally, don't forget about the human element. IIo T is not just about technology. It's also about people. Make sure your employees are trained and engaged in the process. Be sure to monitor constantly and keep up with technological advancements. Continuous learning and improvement are critical for long-term success.

Deep Dive into Predictive Maintenance

Predictive maintenance is the holy grail of IIo T in manufacturing. It's about using data to predict when a machine is likely to fail and schedule maintenance before it causes a disruption. This can significantly reduce downtime, extend equipment lifespan, and improve overall efficiency.

The key to predictive maintenance is collecting and analyzing data from sensors embedded in machines. This data can include vibration, temperature, pressure, and other parameters. By analyzing this data, manufacturers can identify patterns that indicate a potential failure. For example, if the vibration level of a machine starts to increase over time, it could be a sign that a bearing is wearing out and needs to be replaced. There are various machine learning algorithms that can be used to predict equipment failures. These algorithms can be trained on historical data to identify the patterns that are most likely to lead to a breakdown. Once a potential failure is identified, the system can automatically generate a maintenance work order. The work order can include instructions on how to repair the machine and a list of the parts that need to be replaced. This ensures that maintenance is performed proactively, before a failure occurs.

Tips for Implementing IIo T in Your Factory

Successfully integrating IIo T into your smart home manufacturing plant requires careful planning and execution. Here are some practical tips to help you navigate the process.

Start with a clear vision and strategy. Define your objectives and how IIo T will help you achieve them. Identify the key performance indicators (KPIs) you'll use to measure success. Ensure executive buy-in and support. Assemble a cross-functional team with representatives from IT, operations, and engineering. Choose the right technology partners. Select vendors with experience in IIo T and a proven track record in your industry. Implement a robust cybersecurity strategy. Protect your data and systems from cyber threats. Invest in employee training. Equip your workforce with the skills they need to operate and maintain the IIo T system. Embrace a data-driven culture. Encourage employees to use data to make decisions and continuously improve processes. Continuously monitor and optimize the system. Track KPIs and make adjustments as needed to ensure that the system is delivering the desired results. Remember that IIo T is a journey, not a destination. Be prepared to adapt and evolve as your needs change.

Security Implications of IIo T

As you connect more devices and systems to the internet, it's crucial to address the security implications of IIo T. A breach in your manufacturing plant can have devastating consequences, including data theft, production disruptions, and damage to your reputation.

Implement a multi-layered security approach. This should include firewalls, intrusion detection systems, and data encryption. Secure your network. Segment your network and restrict access to sensitive data. Implement strong authentication and authorization controls. Use strong passwords and multi-factor authentication. Regularly update your software and firmware. Patch vulnerabilities to prevent attackers from exploiting them. Monitor your systems for suspicious activity. Use security information and event management (SIEM) tools to detect and respond to threats. Train your employees on security best practices. Educate them about phishing scams, malware, and other threats. Conduct regular security audits and penetration tests. Identify and address vulnerabilities in your systems. Develop a security incident response plan. Be prepared to respond quickly and effectively in the event of a breach.

Fun Facts About Smart Home Manufacturing

Did you know that the first smart home device was invented in 1966? It was a computerized kitchen device that could automate meal preparation. While it wasn't quite the smart home we know today, it was a significant step in the evolution of connected devices.

Another fun fact is that the market for smart home devices is expected to reach hundreds of billions of dollars in the coming years. This growth is being driven by increasing consumer demand for convenience, energy efficiency, and security. Smart home manufacturing is a key enabler of this growth, allowing manufacturers to produce these devices more efficiently and cost-effectively. And speaking of cost-effectiveness, smart home devices are becoming more affordable, making them accessible to a wider range of consumers. This is due in part to advancements in manufacturing technology and economies of scale. Finally, smart home devices are becoming increasingly integrated with each other, creating a seamless and connected experience for users. This requires manufacturers to collaborate and develop interoperable standards.

How to Get Started with IIo T in Your Plant

Feeling overwhelmed by the prospect of implementing IIo T in your smart home manufacturing plant? Here's a step-by-step guide to help you get started.

First, assess your current state. Identify your pain points, challenges, and opportunities for improvement. Determine your goals and objectives. Define what you want to achieve with IIo T. Select a pilot project. Start with a small, manageable project that will deliver tangible results. Choose the right technology partners. Select vendors with experience in IIo T and a proven track record in your industry. Develop a detailed implementation plan. Outline the steps you'll take to implement the system, including timelines, resources, and responsibilities. Secure executive buy-in and support. Ensure that senior management is committed to the project and provides the necessary resources. Implement the system. Install the sensors, connect the devices, and configure the software. Test the system. Verify that the system is working correctly and delivering the desired results. Train your employees. Educate them on how to use the system and interpret the data. Monitor the system. Track KPIs and make adjustments as needed to ensure that the system is delivering the desired results. Continuously improve the system. Adapt and evolve as your needs change.

What If We Don't Embrace IIo T?

The manufacturing world is changing rapidly, and those who fail to adapt will be left behind. Ignoring the potential of IIo T in smart home manufacturing comes with significant risks.

First, you'll fall behind your competitors. Companies that embrace IIo T will be able to produce smart home devices more efficiently, cost-effectively, and with higher quality. You'll struggle to compete on price and features. Second, you'll miss out on opportunities for innovation. IIo T provides access to vast amounts of data that can be used to identify new product opportunities and improve existing products. You'll be unable to innovate as quickly as your competitors. Third, you'll face increasing costs. Without IIo T, you'll be less efficient, have more downtime, and waste more materials. Your costs will continue to rise, making it even harder to compete. Finally, you'll struggle to attract and retain talent. The best and brightest employees want to work for companies that are using the latest technology. You'll have difficulty attracting and retaining skilled workers. In short, failing to embrace IIo T will put your smart home manufacturing plant at a significant disadvantage. You'll be less competitive, less innovative, and less profitable. The future of manufacturing is connected, and those who don't join the revolution will be left behind.

Top 5 Benefits of IIo T in Smart Home Manufacturing (Listicle)

Here's a quick rundown of the top 5 benefits of implementing IIo T in your smart home manufacturing plant:

1. Increased efficiency: IIo T enables you to optimize your production processes, reduce downtime, and improve overall efficiency.

- Reduced costs: IIo T helps you to reduce waste, improve inventory management, and lower energy consumption, leading to significant cost savings.

- Improved quality: IIo T enables you to monitor product quality in real-time, identify defects early, and prevent them from reaching customers.

- Enhanced innovation: IIo T provides access to vast amounts of data that can be used to identify new product opportunities and improve existing products.

- Greater agility: IIo T enables you to respond quickly to changing market demands and customer needs.

Question and Answer about Smart Home Manufacturing Plant: Industrial Io T

Q: What is the biggest challenge in implementing IIo T in a smart home manufacturing plant?

A: One of the biggest challenges is integrating legacy equipment with new IIo T technologies. Many manufacturing plants have older machines that were not designed to be connected to the internet. Integrating these machines requires specialized expertise and can be costly.

Q: How can I measure the ROI of IIo T in my smart home manufacturing plant?

A: The ROI of IIo T can be measured by tracking KPIs such as reduced downtime, improved efficiency, reduced costs, and increased product quality. You can also measure the impact on customer satisfaction and market share.

Q: What are the key security considerations for IIo T in a smart home manufacturing plant?

A: Key security considerations include protecting your network from cyber threats, securing your data, implementing strong authentication and authorization controls, and training your employees on security best practices.

Q: How can I ensure that my IIo T system is scalable and adaptable to future needs?

A: To ensure scalability and adaptability, choose an IIo T platform that is designed to be flexible and modular. Use open standards and protocols to ensure interoperability with other systems. Invest in employee training to keep your workforce up-to-date on the latest technologies.

Conclusion of Smart Home Manufacturing Plant: Industrial Io T

The integration of the Industrial Internet of Things into smart home manufacturing plants is no longer a futuristic concept; it's a present-day reality. By embracing connectivity, data-driven insights, and advanced automation, manufacturers can unlock unprecedented levels of efficiency, quality, and innovation. While challenges remain, the potential rewards are simply too great to ignore. The future of smart home technology hinges on the smart factories that produce it, and IIo T is the key to unlocking that future.

Post a Comment